When there is a problem with the core shooting machine, the manufacturers will be very anxious and want to fix it as soon as possible and continue to use it, but do you know the cause and solution of the core shooting machine failure, how to solve the problem of core shooting machine? Here are some solutions from Delin Machinery.

Knowledge - We Are Professional In Casting/Polishing/Machining

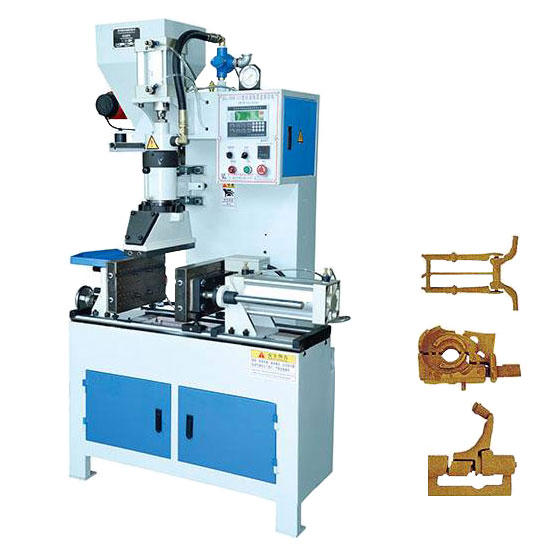

In the foundry industry, the most widely used core making equipment is the core shooting machine. The sand core produced by the machine has accurate dimensions and a smooth surface. The working principle of the core shooting machine is to shoot the core sand mixture with liquid or solid thermosetting resin as the binder into the heated core box.

The core shooting machine is widely used in the foundry industry. However, if the core shooting machine’s operating rules are not standardized, the core size manufactured by the core shooter will not always standard and the surface is not always smooth. It will bury potential safety hazards in the production of machinery, so it is important to know the core shooting machine operating rules. This article takes DL-361 automatic core shooter machine with a nylon conveyor belt as an example to show you the machine’s operating guide.

When the sand core shooting machine starts to run, the daily maintenance and maintenance of the machine is crucial, and problems such as fault repair will also follow.

So how do we do the maintenance of the core shooting machine and how to repair the machine failure. This article takes DL-300-Z hot core box core shooting machine as an example to make a specific analysis.

After the purchased core shooting machine is transported to the destination, the technician has not reached the customer’s factory. We can first understand some knowledge about the installation of the machine, such as how to install the core shooting machine, how to adjust it, what is the operation steps of the machine and what problems need to be paid attention to during the operation. This article takes DL-300-Z hot core box core shooting machine as an example to answer the above questions for you.

This article takes the heat core box sand core shooting machine as an example to analyze the main structure and working principle of the core shooting machine.

The core shooting machine is simply a machine developed for the production of sand cores for castings. It is also called a core making machine. The working principle of this core shooting machine is to use compressed air to evenly shoot the core sand into the core box. Pre-compact, then apply pressure to compact, and finally take out the sand core.

Delin Company invented low pressure die casting machine with improved structure, patent number: CN105964982B, application publication date: 2018-01-19. The entire process of the production equipment is completed automatically, which not only meets the requirements of product processes, improves product quality, but also simplifies the layout of the equipment, this new invented not only reduce production costs but also reduce the space occupied by the equipment corresponding to each process and improve the workshop usage rate.

In order to allow the low pressure casting machine to proceed smoothly in the production process and reduce the frequency of failures, how to maintain the low-pressure casting machine and extend the service life of the machine as much as possible is a problem that foundry manufacturers need to take seriously. If the machine is well maintained can effectively improve the production efficiency of the factory.

The low pressure casting machine is widely used in the production of aluminum, copper and zinc alloy castings in automobiles, motorcycles, instrumentation, textile machinery and aerospace industries. The principle of the low pressure casting machine is mainly to fill the sealed protective furnace with a certain amount of dry compressed air. Under the action of air pressure, the metal liquid in the holding furnace is punched into the mold cavity along the liquid riser to make the metal liquid in the mold cavity. It solidifies internally (under pressure) to obtain a compact casting. Next, Delin Machinery will show you what are the common faults of low pressure casting machines and what solutions are there.