Working hours:Mon - Sat 8.00 - 18.00 Call Us: (+86) 13960339790

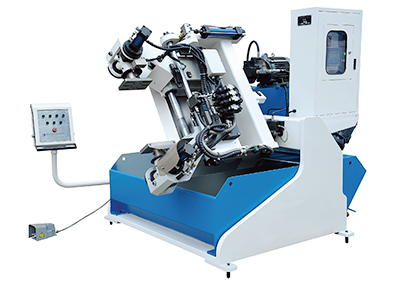

Low Pressure Casting Machine

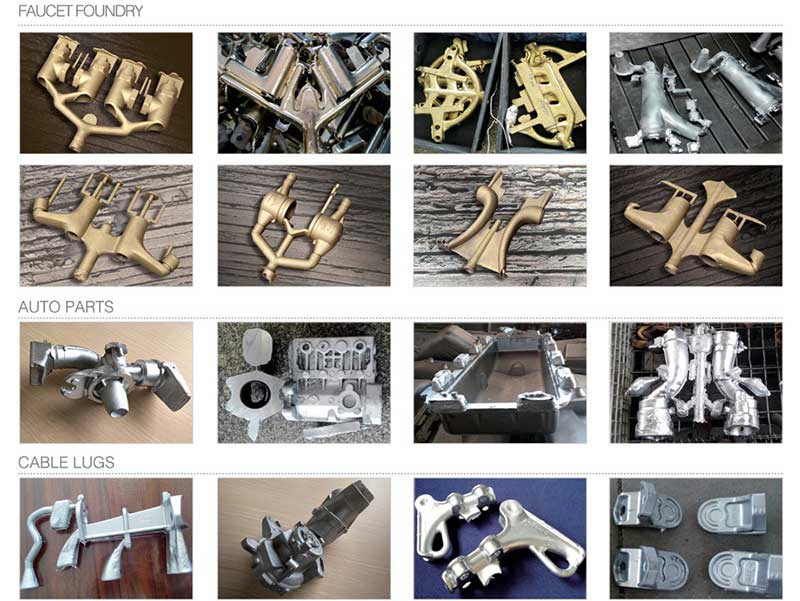

Low-pressure casting machine is a general equipment for the low-pressure casting of copper alloy and zinc alloy, which can be widely used in the production of copper and zinc alloy castings in automobiles, motorcycles, instruments, textile machinery and aerospace industry.

Product Description

- Application: The low-pressure casting machines have widely used a casting of copper alloy & zinc alloy products.

- Main structure: Main machine, furnace, pick-up material truck, graphite tank, mold washing room, hoist crane and control system, hydraulic system, pouring system, pneumatic system.

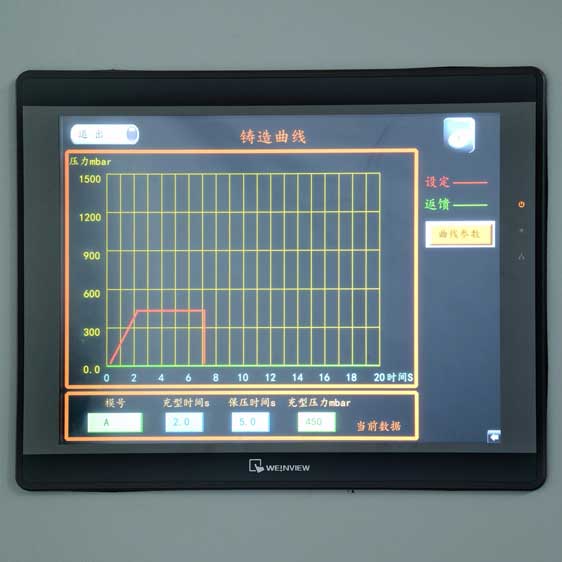

- The Control system adopts Siemens PLC controller, the mechanical hand sideway adopts a servo driver and is fast, stable in performance and highly-accurate in control.

- Furnace capacity 1.8T, melting rate 350kg/h, jacket-cooling water and pressure testing available for non-polar power and pressure adjusting, every inductor coil.

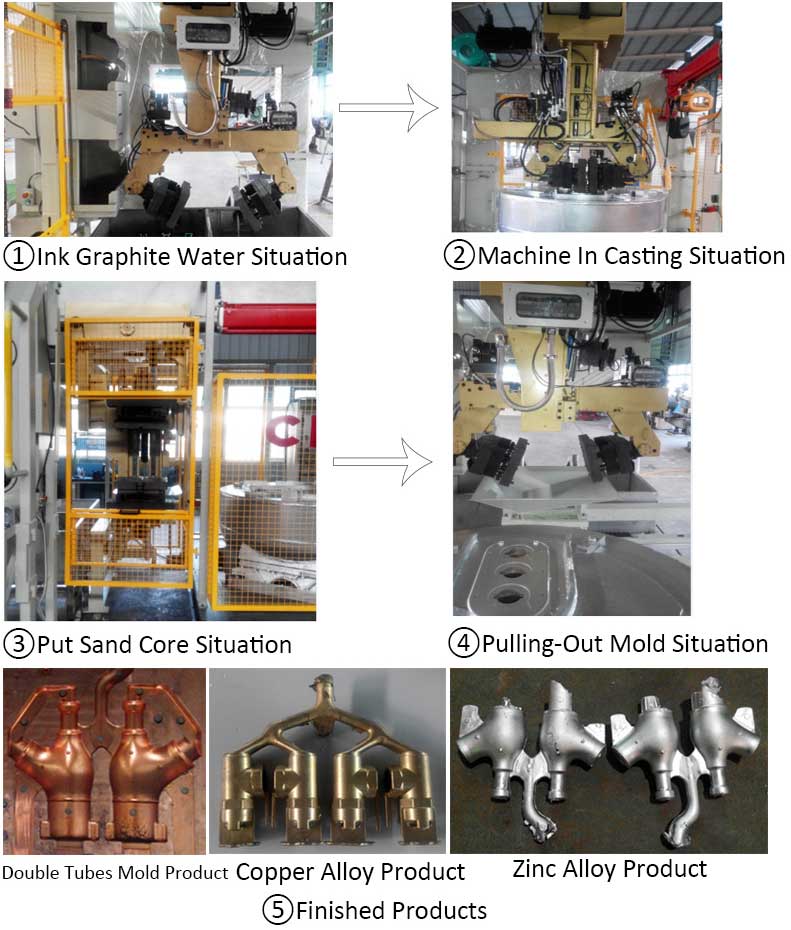

- Feeder machine: Front and back, up and down swinging function available, be able to send the products to the storing cart.

- Mold washing chamber: The mold can be automatically sent to the mold washing chamber for cleaning in case of too much oxide on the mold.

- Electric chain block: Effective lifting 500kg, mainly used for the furnace lifting while furnace cleaning.

- Graphite cuvette: Constant temperature and graphite mixing function available.

- Hydraulic system adopts the international famous brand composition: SUN, REXROTH, YUKEN and so on, with stable performance, strong pollution resistance, suitable for the special water-based hydraulic oil operation components.

- Furnace casting system: Adopts the brand pneumatic components like NORGREN, FESTO, proportion pressure control, and the protection of double safety valves, ensures the casting quality and safety.

- The Chinese(English) display touch panel set various functions and parameters, easy to operate and has a fault code display for easy maintenance.

Low-Pressure Casting Machine Application

Low-pressure casting machine is mainly suitable for producing wall-thickness castings and large-scale castings and some castings with complex structures.

Machine Display

Machine Working Process

Technical Parameter |

|

| The Dimension of Machine | 5000 * 4600 * 3400 mm |

| Equipment Power | 120 kW(Copper alloy) |

| Maximum of Mold Weight | 180kg |

| Maximum Size Of Mold | 500 * 400 * 250 (Thickness) mm |

| Furnace Power | 3 * 35 kW |

| Tube Quantity | 3 |

| Melting Rate | 350 kg / h |

| Pneumatic Pressure | 6kg |

| Water Pressure | 3kg |

| Different Brands of Hydraulic System | SUN,REXROTH,YUKEN etc. |

| Mark | * some parameters can be customized by the client’s requirement. |

CONTACT

Quick Contact

Welcome to contact us to get more information.