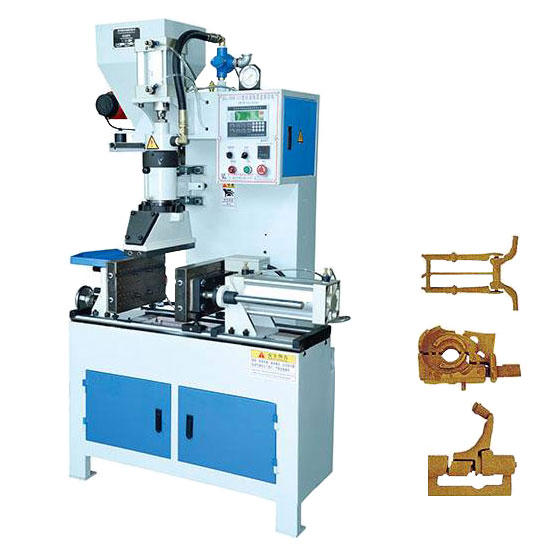

What Is Core Shooting Machine?

The core shooting machine is simply a machine developed for the production of sand cores for castings. It is also called a core making machine. The working principle of this core shooting machine is to use compressed air to evenly shoot the core sand into the core box. Pre-compact, then apply pressure to compact, and finally take out the sand core.

The core shooting machines specific process is

When the work starts, the core box is placed on the worktable, and the worktable rises to press the core box and the bottom plate tightly. When sand-blasting, open the injection pressure valve, and the compressed air in the gas storage tank enters the sand-blasting cylinder through the gap on the sand-blasting cylinder. Therefore, the high-speed sand flow formed by the core sand is injected into the core box from the sand injection hole, and the core sand is compacted, and the air is discharged into the atmosphere from the sand injection head and the exhaust hole of the core box. Sand compaction can complete the two processes of sand filling and sand compaction together, so the productivity is very high.

Taking the production process of the hot core box core shooting machine as an example, the working principle of the core shooting machine is introduced: the mixture of liquid or solid resin and the curing agent of the sand core is injected into the heated core box. After rapid hardening to a certain thickness (5 to 10mm), the sand core is removed, and the sand core becomes a high-quality sand core with a smooth surface and precise dimensions.

Core shooting machine is classified according to the core shooting direction: divided into two types of vertical and horizontal sand making core and shape.

The structure of the whole machine is mainly composed of four major parts.

1. Column components: the upper frame of the equipment is mainly composed of beams and columns. Sand barrel, sand hopper and sand valve are installed on the beam

Components, compacting cylinders and other parts constitute the core-making sand and air supply system.

2. Sandblasting device: it consists of a sand barrel, air valve, sand barrel rack, shooting head, sandblasting board and other parts. Pressing cylinder when working

Press the sand cylinder tightly on the upper surface of the core box, and open the sand injection valve to perform the sand injection. After exhausting the sand shot, loosen the compression cylinder (return to the original position) to complete the sand shot and sand addition work

3. Mold frame components: mainly composed of moving template, left and right bracket plates and guide columns, guide sleeves, ejector rods, mold clamping cylinder and other components.

3.1 The entire formwork is installed on the base by the left and right bracket plates

3.2 The movable template moves along the guide column under the push and pull of the mold clamping or moves up and down to complete the core making process of mold clamping and mold opening. When the mold is opened, the core on the top core plate is pushed out by the top rod of the fixed template, and it can be easily removed by hand.

3.3 Base: The support, formwork, uprights, electric control box, solenoid valve, etc. of the entire equipment are mounted on it.

Core shooters are classified according to the type of core making:

(1) Ordinary core shooting machine, that is, ordinary core making. It uses a common core box (wood or metal), which is injected into ordinary core sand (mostly oil sand or synthetic sand). After shooting the core, the core is taken out from the core box, and then it is placed in the oven to dry. hardening. With the development of resin sand, this method of core making has been gradually replaced.

(2) Hot core box core shooting machine, that is, hot core box core shooting. An electric heating plate is provided on the core shooter to keep the core box insulated at 200-250 ° C. Since the injected core sand is furan resin sand, which is a thermosetting material, the core can be hardened in the core box in about 60 seconds. Compared with the traditional core making method, the hot core box core making eliminates the need to place core bones and drying procedures, high productivity, accurate core size, smooth surface, high strength, suitable for manufacturing various complex on the automobile, tractor castings Core.

(3) Cold core box core shooter, that is, cold-core box core making. It refers to a core box at normal temperature, and aerosol hardener is applied after the core is fired, so that the special resin sand is rapidly hardened through a chemical reaction. This core-making method requires the use of a special core-shooting machine. The cores produced have accurate dimensions and high productivity and are a promising method for core-making.

In addition, a new type is the shell core machine core. It uses phenolic resin sand, which is filled and compacted by the sand blowing method. Since the core box is preheated to 200-280 ° C by an electric hot plate, after 20-60 seconds of heat preservation, the core sand is formed into a thin 3-10mm because of the resin melting. At this time, the core box is turned over, shaken, and loose core sand is poured out to form a hollow shell core. Then continue to heat for 30 to 90s to make a stronger shell core. The shell core not only saves resin sand, but also facilitates the exhaust of the core, and has been widely used in the manufacture of complex cores on automobiles.

It should be noted that the disadvantage of using resin sand to make the core is that irritating odor gas or harmful gas is emitted during hardening, and the environment should be kept sealed and ventilated.

The produced sand core is widely used in foundry industries making products like automobile valves, hardware sanitary fittings, water tap, cast iron, cast copper and cast aluminum, etc.

Compared to common core shooter, advantages of the heated core box shooter are as followed:

- High productivity: during the working process of heated core box shooter, sand-filling and compaction are completed simultaneously while the sand core will be immediately hardened in the heated core box. A cycle period only lasts for ten-odd seconds to tens of seconds during which the sand core for cast use is produced.

- High quality of sand core: the sand core of any complicated level can be shot and with a precise dimension and smooth surface, hence, the casting process redundancy is reduced and the cost is lowered.

- Many assisting types of equipment and tools used for core-making become unnecessary, such as core drier, core carrier, core rod and strum, etc.

- Labor intensity is reduced with flexible and easy operation; the temperature can be controlled automatically with electrical heating; favorable conditions are created for mechanization and automation during the core-making process since it is easy to keep the working site clean.

- This machine possesses two functions at the same time: both dried sand and wet sand can be shot.

Delin Machinery is a well-known Chinese foundry machinery manufacturer, which can provide quotation and export of core shooting machines to various countries. You can click here: gravity casting machine to view more details of our casting machine products. If you want to know more details like are we manufacturers? machine function? support video and more pictures? price list? how to buy? Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: [email protected]