How to better start core shooter effectively?

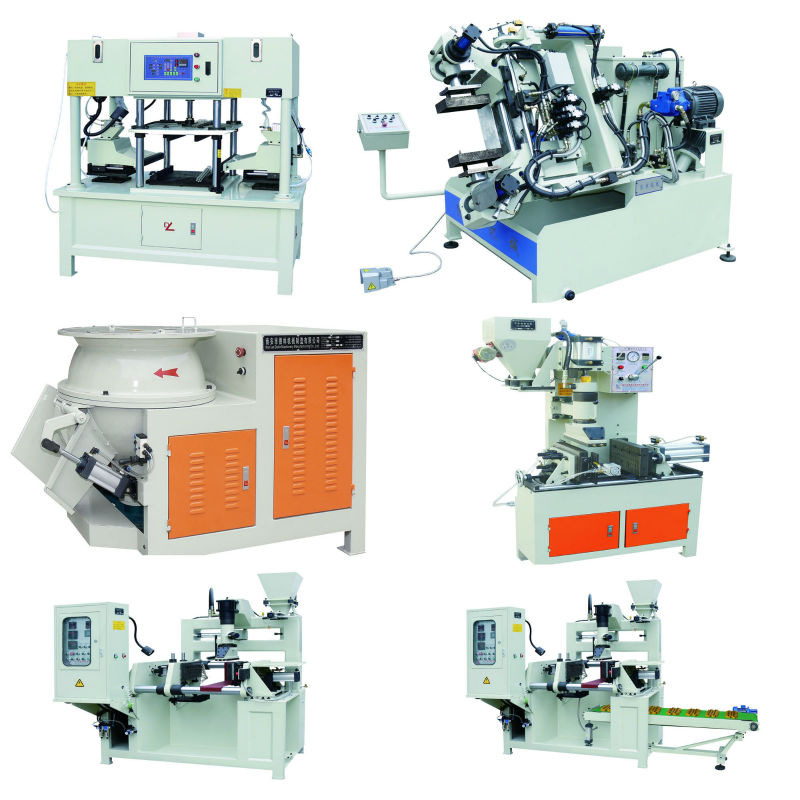

Abstract: ①The control method of the running state after the core shooter is started; ②Preparations required before the core shooter equipment is started; ③The workflow required by the core shooter after use.

The control method of the running state after the core shooter is started:

1. During the production process, if it is found that the jarring force of the core shooting machine is weak, or the pressure is weak, or the turning force is weak, or the clamping force is weak, the maintenance personnel should be notified to check and repair.

3. In the production process, the core shooter and its surroundings are often treated with sand accumulation to prevent sand from entering the cylinder.

4. When hanging the sandbox, do not allow the sandbox to hit the model or the door handle, so as not to damage the model or cause misoperation.

2. If the core shooting machine fails, the operation of the equipment should be stopped immediately, the on-site status should be maintained, and the relevant departments should be reported, inspected, analyzed, and dealt with.

5. Always pay attention to the working state of the core shooter. If there is poor lubrication, loose fasteners, damaged parts, leakage of pipes, and other abnormal phenomena, it should be stopped immediately and the maintenance personnel should be notified for maintenance.

6. Always keep the shock piston working in a lubricated state, blow sand to the piston regularly, and then spray oil.

7. After the core shooting machine is turned on, the operator should not leave the work post without permission, should concentrate his mind and operate it carefully according to the process regulations, but cannot operate two doors at the same time.

The 11 electromagnetic switching valves (plate type) of the pneumatic circuit of the core shooting machine are respectively installed on the upper, middle, and lower piping plates of the valve box. Solenoid valves have different structures and are difficult to replace. In order not to affect production, reduce the cost of transformation, facilitate the manufacture, operation, and maintenance, a gas distribution plate with a length of 122mm, a width of 48mm, and a thickness of 25mm is designed as the air passage connecting the new solenoid valve and the valve body gas distribution plate. The new standard The valve is used without being installed on the core unit.

Preparations required before the core shooter machine is started:

1. Before starting, check whether there are guiding objects in the moving parts, and the equipment operator is close to it. Do not place tools and other debris on the device.

2. When the running equipment suddenly stops working due to the interruption of the external power supply, it is necessary to cut off the power switch of the equipment to avoid the danger caused by re-calling; in the process of equipment maintenance, inspection, adjustment, and cleaning, the main power supply, and compression should be cut off. Air main valve.

3. Manual idle speed before automatic operation; when the equipment is running, it is not allowed to touch moving parts and electrical components.

Fourth, the operation of the core shooting machine equipment is trained employees, untrained personnel can not operate the equipment.

5. After the equipment is working, stop the machine in the original position, and then cut off the power supply and air supply.

6. When there are abnormal phenomena such as abnormal sound and smell, all parts of the equipment should stop running immediately, and carry out a manual idling test after inspection and adjustment.

The workflow required by the core shooter after use:

1. Deposit sand on the gate, and coat graphite powder on the gate to reduce friction.

2. Fold down the sand shooting head, clean up the sand and sticky sand, and clean it up for the next use.

3. Take out the sand shooting cylinder, take out the sticky sand in the gap, wipe the inner wall with paraffin, but do not block the gap.

4. Dust and sand are deposited on the guide rails and guide rods, and apply a layer of lubricating oil.

5. Carefully clean the sticky sand in the exhaust plug.

6. Operate all electrical switches, restore the equipment and mechanisms to their original positions, and then cut off the power and air supply.

The working process of the core shooter is completed at the same time as sand filling and compaction, and it is immediately hardened in the hot core box, reducing labor intensity, flexible and light in operation, easy to master, using electric heating, the temperature can be automatically controlled, and the working place is easy to keep clean, to create conditions for the mechanization and automation of the core making process. Sand cores for casting can be produced in a cycle of only ten to several tens of seconds.

You can click here: automatic sand core shooting machine to view more machine introduction, and maybe you are interested in the machine working video: core shooting machine working process video.

By the way, If the machine is purchased from our company, we have technicians to come to install and train. If you want to know more information like are we manufacturers, machine function, support video, and more pictures, price list, how to buy, Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: salse16@chinamakeco.com