The latest structural design of low pressure die casting machine

Delin Company invented low pressure die casting machine with improved structure, patent number: CN105964982B, application publication date: 2018-01-19. The entire process of the production equipment is completed automatically, which not only meets the requirements of product processes, improves product quality, but also simplifies the layout of the equipment, this new invented not only reduce production costs but also reduce the space occupied by the equipment corresponding to each process and improve the workshop usage rate.

The new design of low pressure die casting machine with improved structure

This article is the specific analysis of the invention patent

Full-text summary

Low pressure die casting machine with improved structure includes a frame and a low-pressure die casting manipulator installed and walking on the frame. A mold cooling station, a casting unloading station and a casting pouring station are sequentially arranged below the frame. The mold cooling station is provided with a mold cooling device, the casting unloading station is provided with a low-pressure casting receiving vehicle, and the casting filling station is provided with a casting liquid induction furnace. The invention inverts a low-pressure casting manipulator on a single support beam of a rack so that the manipulator can be displaced to a mold cooling device, a low-pressure casting receiving vehicle and a casting liquid induction furnace to complete mold cooling and casting discharge respectively And the three independent processes of casting and pouring. The entire process is completed automatically, which not only meets the requirements of product processes, improves product quality, but also simplifies equipment layout, which can not only reduce production costs, but also reduce the space occupied by the equipment corresponding to each process, and improve the utilization rate of the workshop.

Patent name: a kind of low pressure die casting machine

Technical Field: The present invention relates to low-pressure casting production equipment, in particular to low pressure die casting machine with improved structure.

Background technique

Low-pressure casting is a method to make liquid metal fill the cavity under pressure to form a casting. Due to the low pressure used, it is called low pressure casting. The process of low-pressure casting is: in a sealed furnace, dry compressed air is passed, and the metal liquid rises along the riser tube under the action of the gas pressure, enters the cavity smoothly through the gate, and maintains the liquid level in the furnace Gas pressure until the casting is completely solidified. Then the gas pressure on the liquid surface is relieved so that the unsolidified metal liquid flow furnace in the liquid opening tube is opened by the cylinder and pushed out of the casting.

In the prior art low-pressure casting machine, due to certain limitations of the equipment, the smoothness of the movement between the moving parts is poor, which often leads to a decrease in the accuracy of the casting; at the same time, the traditional low-pressure casting machine has a low degree of automation, after the casting is completed It is often impossible to quickly remove the castings, and the adaptability to different specifications of the mold is also poor, and the production efficiency is low.

The Chinese invention patent application discloses a low-pressure casting machine, which realizes vacuum negative pressure lifting through a high-temperature vacuum pump, and at the same time sets the core-pulling frame and moving template as an integral type and controls the lifting through the clamping oil cylinder, thereby enhancing the mold for different specifications The applicability of the machine, through the setting of the core connection platform and the core trolley, realized the rapid removal of castings, and the production efficiency was higher.

Although the above low-pressure die casting equipment can be adapted to different specifications of molds, there are still the following defects in the actual use process: 1, because each time casting is completed, it is often necessary to cool and clean the mold in order to remove the last time The impurities left in the casting process, and the above equipment has no relevant structure, which will seriously affect the quality of the casting. 2. Because the temperature of the casting liquid in the holding furnace is extremely high, and the receiving position of the receiving trolley is arranged above the holding furnace, it is easy to deteriorate the working environment of the receiving trolley, reduce its service life, and easily lead to increased production failures, which is not conducive to large Large-scale high-efficiency production.

Summary of the invention

The invention provides low pressure die casting equipment with improved structure, and its main purpose is to overcome the defects of the existing low-pressure die casting machine that there are many production failures and the casting product quality is not high.

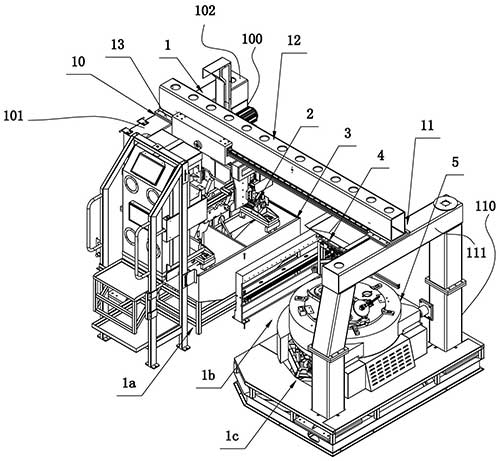

2 Manipulator

3 Mold cooling device

4 Low-pressure casting receiving truck

5 Casting liquid induction furnace

10 The first side stand body

11 The second side stand body

12 Support beam

13 Rail assembly

100 First support column

101 First stringer base

102 Tank space for hydraulic oil

110 The second support column

111 Second stringer base

1a Mold cooling station

1b Casting unloading station

1c Casting filling station

To solve the above technical problems, the present invention adopts the following technical solutions:

Refer to figure 1, Low-pressure die casting machine with improved structure, including

1. Frame 1 and low-pressure casting manipulator 2 installed and walking on the frame 1

2. The mold cooling station la, the casting unloading station lb, and the casting filling station lc are arranged in the order in the rack 1 below the walking area of the low-pressure casting manipulator 2.

A. The mold cooling station la is provided with a mold cooling device 3

B. The casting unloading station lb is provided with a low-pressure casting receiving truck 4

C. The casting liquid filling station lc is provided with a casting liquid induction furnace 5

3. The frame 1 includes a first side vertical frame body 10, a second side vertical frame body 11 and a support beam 12 fixed at the middle of each side vertical frame body 10 and 11 at two ends, and the support beam 12 is rail assemblies 13 are provided on both sides in the longitudinal direction

4. The low-pressure casting manipulator 2 includes a sliding guide seat, a driving mechanism installed on the sliding guide seat and used to drive the walking, a lifting frame body installed at the bottom of the sliding guide seat, a mold clamping frame body, fixed swing arm and a movable swing arm movably installed in the mold clamping frame

A. A lifting mechanism for controlling the mold clamping frame body to move up and down is installed in the lifting frame body

B. A mold clamping mechanism for controlling the movable swing arm to move left and right is installed in the mold clamping frame body

C. The first mold is installed at the end of the fixed swing arm

D. The end of the movable swing arm is installed with a second mold matching the first mold

E. The sliding guide seat is respectively provided with a slider assembly adapted to the guide rail assembly 13 at a position corresponding to each guide rail assembly 13

Compared with the prior art, the beneficial effects of the present invention are:

- In the present invention, the low-pressure casting manipulator 2 has a simple structure and low cost. Its main parts are divided into three parts, a lifting mechanism 26, a mold clamping mechanism 27, and a swing arm composed of a fixed swing arm M and a movable swing arm 25. The mechanism completes the three production actions of up and down expansion, arm claw opening and closing, and mold folding, which not only meets the production needs, but the entire production control action is controlled by hydraulic pressure, which has high control accuracy and low cost. It can be used for zinc alloy and The casting of various small parts of copper alloy can not only greatly reduce the internal porosity of the product and improve the quality of the product, but also the cost is much lower than that of other industrial robot arms controlled by servo motors, which is welcomed by the majority of manufacturers.

- The invention has a simple structure and strong practicability. By inverting a low-pressure casting manipulator on a single supporting beam of a rack, the low-pressure casting manipulator can be moved to a mold cooling device, a low-pressure casting receiving vehicle and a casting liquid Three independent processes of mold cooling, casting unloading and casting filling is completed on the induction furnace, the entire process is completed automatically, so as to not only meet the requirements of the production process, improve product quality, but also simplify the equipment layout and support the beam. It is versatile and can be used as a rack as well as a guide rail, thereby reducing production costs, reducing the space occupied by the equipment corresponding to each process, and improving the utilization rate of the workshop.

- In the present invention, the structure of the low-pressure casting manipulator is simple and the cost is low. Its main part is divided into three parts, the lifting mechanism, the mold clamping mechanism and the swing arm mechanism composed of a fixed swing arm and a movable swing arm, which respectively complete the up and down The three production actions of telescoping, arm claw opening and closing, and mold folding not only meet the production needs, but the entire production control action is controlled by hydraulic pressure, which has high control accuracy and low cost, and can be used for various zinc alloy and copper alloy. The casting of small parts can not only greatly reduce the internal pores of the product and improve the quality of the product, but also the cost is much lower than that of other industrial robot arms controlled by servo motors, which is welcomed by the majority of manufacturers.

- In the present invention, by setting the graphite tank into an inner and outer plate structure, and effectively using the interlayer space between the inner and outer plates, it is transformed into a unidirectional flow cooling channel, which not only saves the arrangement of the serpentine tube. The cost required for heat exchange, and can fully save the space in the graphite tank, expand the volume of graphite water to a certain extent, and can effectively solve the difficulty of cleaning and scaling caused by the long-term use of the serpentine tube caused by the accumulation of scale. The problem of reduced heat exchange efficiency greatly improves the service life and heat exchange efficiency of the present invention.

- In the present invention, by designing the first longitudinal girder seat body of the first side upright body as a hydraulic box body that replaces the traditional hydraulic device, it not only makes full use of the existing equipment structure to achieve multi-purpose, and reduces design costs, Moreover, designing the hydraulic oil in a high place can not only reduce the energy consumption of hydraulic operation, but also make full use of the headspace, and at the same time, it is conducive to the neat arrangement of the hydraulic circuit.

- In the present invention, the second side stand body is converted into a built-in ventilation space or a ventilation tube is hidden inside, so as to not only make full use of the existing equipment structure to achieve multi-purpose, reduce design costs, but also to the ventilation tube. The protection can effectively prevent the aging or damage of the vent tube, and it is also conducive to the neat arrangement of the vent line.

- In the present invention, the casting liquid induction furnace can be designed with multiple casting liquid filling inlets (that is, multiple liquid riser seats), so that the user can choose the amount of casting liquid filling according to production needs. This undoubtedly improves the production capacity per unit time, so it is beneficial to further broaden the applicable occasions of the present invention.

- In the present invention, by arranging the electric heating unit at the position of the nozzle of the riser, the problem of poor fluidity of the casting liquid due to the temperature drop when the casting liquid in the furnace body is filled during casting can be effectively solved, ensuring The casting liquid smoothly flows into the mold. The electric heating method not only has a simple structure but also does not generate a fire source. Therefore, it greatly reduces the hidden safety hazards in the production process and is beneficial to improve the working environment of the workshop.

- In the present invention, the lifting cylinder is used to lift the welding hopper of the receiving vehicle. When the welding hopper of the receiving vehicle is located under the manipulator, the lifting cylinder can lift the welding hopper of the receiving vehicle upward to make it closer. The distance between the robot and the manipulator can effectively reduce the impact force of the metal casting on the welding hopper of the receiving vehicle, reduce the mechanical loss suffered by the welding hopper of the receiving vehicle, and thereby extend the service life of the welding hopper of the receiving vehicle. After the material is received, the lifting cylinder can control the welding hopper of the material receiving vehicle to descend, and smoothly cooperates with the driving cylinder and the turning cylinder to complete the traverse feeding and turning and discharging operations.

- In the present invention, by designing a low-pressure casting receiving vehicle, it can be ensured that after each casting is completed, the casting can be automatically taken away and the unloading action can be automatically completed. The whole process is coordinated by three cylinders with different uses Completion does not require manual participation, which can save labor costs and reduce labor intensity.

- In the present invention, by designing the blanking detection unit (which can be a weight sensor or a contact sensor), it can automatically detect whether the casting is dropped, so that the hopper of the receiving car can automatically complete the lifting of the material, the lowering of the return position, and the horizontal feeding. And a series of actions such as flipping and unloading, and can be automatically cycled, which is conducive to improving the degree of automation of the equipment.

Delin Intelligent Technology Co., Ltd. is a machinery manufacturing enterprise which is a professional manufacturer with years of experience in the production of the automatic low pressure die casting machine. We have a professional design and production team to produce a high-quality casting machine. Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: salse16@chinamakeco.com