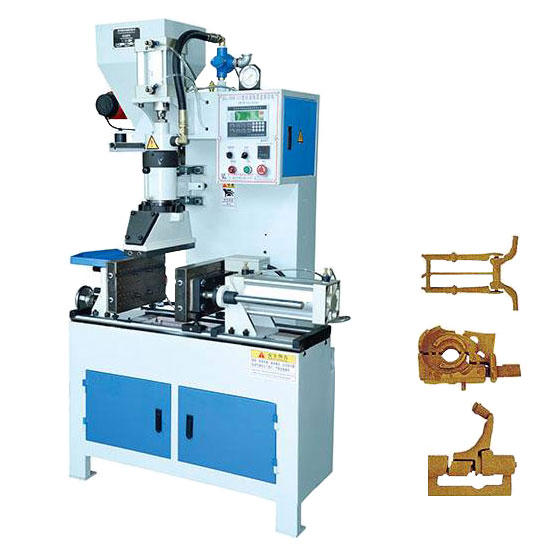

The core shooting machine is simply a machine developed for the production of sand cores for castings. It is also called a core making machine. The working principle of this core shooting machine is to use compressed air to evenly shoot the core sand into the core box. Pre-compact, then apply pressure to compact, and finally take out the sand core.

Blog - We Are Professional In Casting/Polishing/Machining

Delin Company invented low pressure die casting machine with improved structure, patent number: CN105964982B, application publication date: 2018-01-19. The entire process of the production equipment is completed automatically, which not only meets the requirements of product processes, improves product quality, but also simplifies the layout of the equipment, this new invented not only reduce production costs but also reduce the space occupied by the equipment corresponding to each process and improve the workshop usage rate.

In order to allow the low pressure casting machine to proceed smoothly in the production process and reduce the frequency of failures, how to maintain the low-pressure casting machine and extend the service life of the machine as much as possible is a problem that foundry manufacturers need to take seriously. If the machine is well maintained can effectively improve the production efficiency of the factory.

The low pressure casting machine is widely used in the production of aluminum, copper and zinc alloy castings in automobiles, motorcycles, instrumentation, textile machinery and aerospace industries. The principle of the low pressure casting machine is mainly to fill the sealed protective furnace with a certain amount of dry compressed air. Under the action of air pressure, the metal liquid in the holding furnace is punched into the mold cavity along the liquid riser to make the metal liquid in the mold cavity. It solidifies internally (under pressure) to obtain a compact casting. Next, Delin Machinery will show you what are the common faults of low pressure casting machines and what solutions are there.

The application of low pressure casting machines is becoming more and more extensive. How to safely operate low pressure casting machines and ensure personal safety is becoming more and more important. What matters need to be paid attention to in the safe operation of low pressure casting machines, how to operate safely, and what are the operating specifications, this article will give you revealed.

Delin Company invented an industrial robot low pressure casting machine production equipment and the use method of the equipment, patent number: CN102009156A, application publication date: 2011-4-13. The production equipment realizes automated production, reduces the time required for the entire production process, shortens the production cycle, and significantly improves labor efficiency.

When you understand the difference between low pressure casting and gravity casting, you might also want to understand the difference between low pressure and gravity casting for a specific object, such as automobile wheel rims. So this article will talk about why automobile wheel rims choose low pressure casting instead of gravity casting? Are low pressure cast aluminum wheels good?

Delin Machinery is specialized in producing casting equipment such as gravity casting machine and low pressure casting machine. Today we talk about the difference between gravity casting and low pressure casting. No matter what the product is, to judge whether it is good or not, we always use a reference to make a comparison. Only in some cases, A may be more suitable, but in another case, B or C may be more suitable. The same is true for gravity casting and low pressure casting.

After understanding what is low pressure casting, you may also want to learn more about how is low pressure casting works and what is the process of low pressure casting. This article will give you a comprehensive answer.

Low pressure casting means that the casting mold is generally placed above the sealed crucible, compressed air is introduced into the crucible, which causes low pressure (0.06 ~ 0.15MPa) on the surface of the molten metal so that the molten metal rises from the riser tube to fill the casting mold and control solidified casting method. This casting method is well packed, the castings are densely structured, and it is easy to cast large and thin-walled complex castings without risers, and the metal recovery rate is 95%. No pollution, easy to realize automation. But the equipment cost is higher and the production efficiency is lower. Generally used for casting non-ferrous alloys.