Tips for choosing core shooting machine

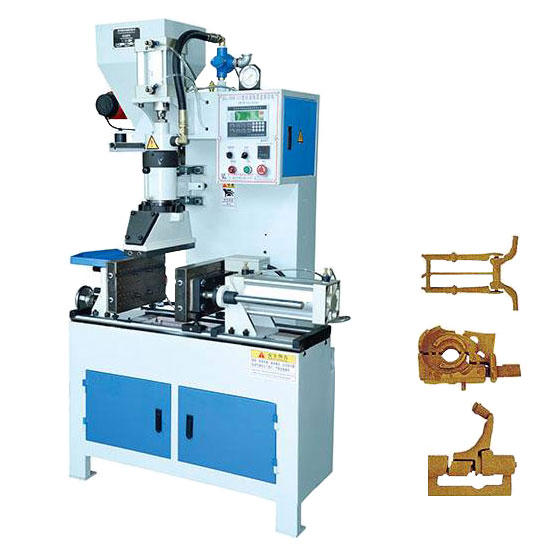

The core shooting machine is more and more widely used in the casting machinery industry. Understanding its purchase points can help us choose the core shooter that suits our needs. Only by choosing a core shooting machine that is suitable for the production of your own products can you achieve a multiplier effect in your future work. There are many types of core shooter machines in the core shooting machine market, and the specific functions provided by different equipment manufacturers are also different. Let’s take a look at how to buy a core shooting machine suitable for your own production.

How to choose a core shooting machine?

The tips for choosing a core shooting machine as following:

1. First of all, whether the core shooting machine model is suitable for yourself, it is very important to choose a core shooter machine suitable for production.

2. The second is to see whether the core making cycle time of a core shooting machine is reasonable. Under the same conditions, the shorter the time, the more reasonable the heating rod distribution and the higher the efficiency.

3. If it is a shape, it is better to choose a dual-position core shooter, because it can achieve a multiplier effect.

4. Do not choose a machine with a high scrap rate. Choose a core shooter product with long life and a high probability of finished products.

5. See if the machine runs seriously. The design of core shooters with serious sand running is often unreasonable, which will greatly increase the consumption of coated sand.

6. See if the core shooter manufacturers provide after-sales service and technical support.

7. The matching casting mold on the core shooting machine is also a very important link. (Factors affecting the life of core shooting machine mold) Whether the design and production of the casting mold on the core shooter directly affect the use efficiency of the core shooter, the pass rate of the products produced by the core shooter machine, etc.

8. The price of the core shooter. When the function of the core shooter machine is determined, choose a more reasonable price, cost-saving, and high-cost performance.

In fact, there are many types of core shooter, and the prices are also uneven, but not the best core shooter machine is the most suitable for their own production.

According to the size and production volume of the products produced, such as mass production of the same product, you can choose the Delin Machinery–double head core shooting machine, because it can produce two or four or eight identical cores at the same time. If you want a more environmentally friendly core shooting machine, you can also choose the Delin automatic core shooter machine

The choice of core shooting machine is not unique and can be selected according to product size, production volume and other specific requirements.

There are many styles of hot core box core shooting machines supplied by Delin Machinery, and a series of production line machines are available. We look forward to your in-depth understanding and purchase. Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: [email protected]