low pressure cast VS gravity cast wheels

When you understand the difference between low pressure casting and gravity casting, you might also want to understand the difference between low pressure and gravity casting for a specific object, such as automobile wheel rims. So this article will talk about why automobile wheel rims choose low pressure casting instead of gravity casting? Are low pressure cast aluminum wheels good?

With the development of automobile culture, more and more people begin to understand the original wheels of their car and the now popular modified wheels. A large number of wheels have been introduced in the market. The wheels are mainly divided into steel wheels and aluminum alloy wheels according to the material. Among them, aluminum alloy wheels are mainly made of aluminum alloy and aluminum-magnesium alloy products. In the current automotive market, there are fewer and fewer steel wheels. Most models use aluminum alloy wheels, mainly casting and forging. The most common casting methods are gravity casting and low pressure casting. Next, let’s understand the production process of these two castings and the reason why automobile wheel rims choose low-pressure casting instead of gravity casting.

Gravity casting

Gravity casting is mainly poured into the mold cavity by the gravity of the aluminum liquid itself. The pressure in the flow comes from the self-weight of the aluminum liquid itself. Gravity casting belongs to the most original casting hand and has a low technical content, so most of them use labor. The level of craftsmanship is difficult to guarantee.

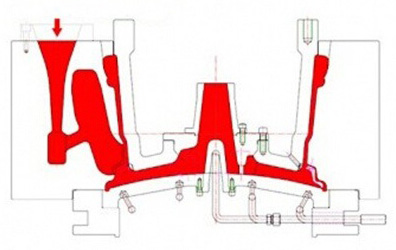

Schematic diagram of gravity cast wheels

Gravity casting:

After the mold is fixed, the aluminum solution is injected into the mold from the pouring port. The aluminum solution is completely filled with gravity to fill the entire mold. After the solidification is completed, the mold is opened, and a gravity casting wheel is basically formed.

Due to the low cost, gravity casting only needs the corresponding mold to start, so it is favored by small domestic factories. However, due to the change of various environmental conditions and the low controllability of artificial casting, the quality during mass production is easy If there are defects, the loss of raw materials will be greater. For car manufacturers with the large demand for wheels, this production method has been completely eliminated, but for auto parts retailers that frequently change styles and are more sensitive to prices, this type of product is more popular, so it is also for this kind of foundry products opened the market.

Low pressure casting

Low pressure casting is that aluminum water enters the mold from the bottom to top under pressure, and the aluminum liquid solidifies and crystallizes under pressure. The whole process is mechanized, so the process level is very stable. In terms of production cost, the cost of low-pressure casting is greater than that of gravity casting. However, in order to ensure the safety of the entire vehicle, most automotive manufacturers now specify the use of low-pressure casting to ensure the quality of the wheel.

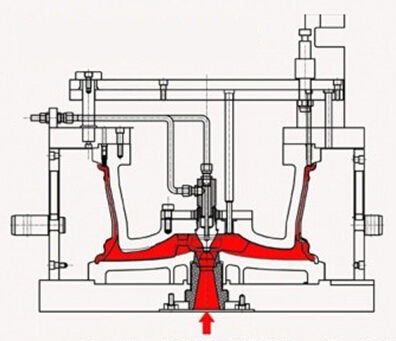

Schematic diagram of low pressure casting wheels

Low pressure casting:

Fix the mold above the closed high-temperature aluminum solution pool. Bypassing dry compressed air into the closed solution pool, the aluminum solution enters the cavity in the mold under gas pressure and maintains the gas pressure of the aluminum solution pool until the entire The casting is complete and it has completely solidified.

Because there is a certain pressure control throughout the casting process, the material density of the casting after molding is better than that of ordinary gravity casting. Under the same circumstances, low-pressure castings can get better performance; in addition, for some particularly complex wheel shape, low-pressure casting It can also be completed, but gravity casting is limited by the liquidity of the aluminum liquid, and some wheels with complex shapes cannot be completed at all, or the yield rate will be greatly reduced.

According to the above separate introduction to the manufacturing process of wheels, we can easily see that low-pressure casting has inherent advantages over gravity casting for technical reasons:

1. The balance of the wheel: the performance of the wheel and the dynamic balance and roundness are good. The dynamic balance performance of the inner and outer wheel diameters less than 30g is far lower than the traditional gravity casting method. The data of the traditional gravity casting is 45g-60g or more. In this way, it is more stable and stable during driving.

2. The organization of the wheel: the pressure is evenly delivered to the wheel mold, which can make the internal organization of the hub denser and greatly improve the safety. Generally, traditional gravity casting does not have any pressure transmission, and the wheel structure is relatively loose.

3. The strength of the wheel: The low-pressure casting method uses low-pressure feeding, which greatly increases the strength of the wheel, at least 30% over gravity casting. For example, the OEM aluminum wheels of major domestic and foreign automobile factories all adopt the low-pressure casting method, which proves that the traditional gravity casting is not stable in terms of strength.

4. The safety of the wheel: The pressure delivery system of the low-pressure casting will not be affected by the environment and climate changes. The production of safe and stable products can be produced throughout the year, and the traditional gravity casting is generally susceptible to climate, temperature and humidity product quality is unstable.

5. Compare with some data that will affect driving comfort:

| Low pressure casting | Unit | Gravity casting | Unit | |

| Dynamic balance | 0-25 | g | 0-60 | g |

| Roundness | 0-40 | mm | 0-60 | mm |

| Parallelism | 0-20 | mm | 0-40 | mm |

| P.C.D Roundness | 0-15 | mm | 0-30 | mm |

| Sand hole deflation rate (before processing) | 0-3% | 0-40% |

From the above data, it is not difficult to see that the performance of low-pressure casting is superior to that of traditional gravity casting. All the data that affects the stability and comfort of driving are relatively strong, so there are excellent balanced low-pressure casting wheels, which are far more than traditional the wheels are gravity cast.

Delin company is a professional manufacturer with years of experience in the production of the low pressure casting machine and gravity casting machine. We have a professional design and production team to produce a high-quality foundry casting machine, can provide quotation and export of casting machines to various countries.

If you want to know more details like are we manufacturers? machine function? support video and more pictures? price list? how to buy? Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: salse16@chinamakeco.com