Design of gravity die casting machine

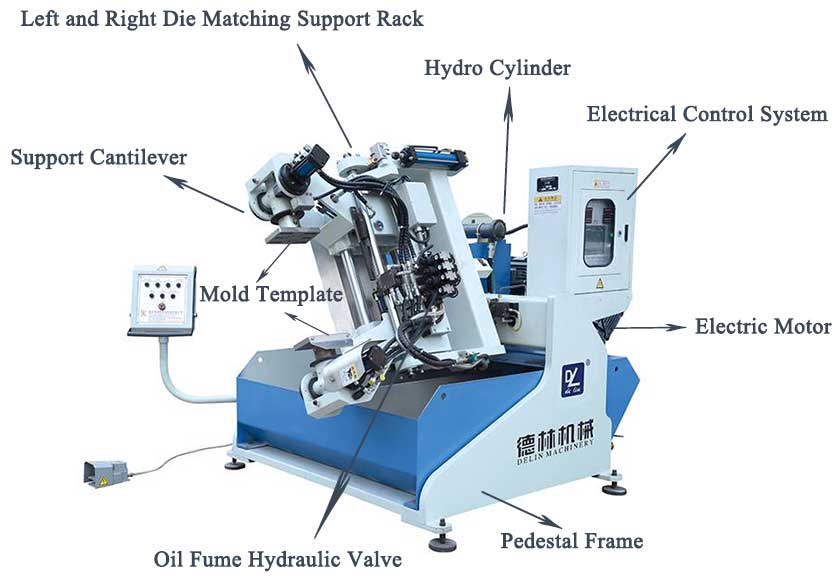

Since 1998, Delin Machinery has been developing gravity die casting machines to meet various production requirements. We have extensive experience in developing and designing efficient gravity casting machines for different molds. Our equipment can be provided separately or as an overall solution for nonferrous series casting equipment. Next, Delin Machinery takes you to understand the structure and working principle of the gravity die casting machine.

You can also click the YouTube video link here: “Design of gravity die casting machine” watch the video to understand the structure and working principle of our gravity casting machine more clearly and intuitively.

Gravity casting machine generally refers to the machine that realizes the opening, closing and taking of metal gravity casting. Metal-type gravity casting refers to a process method in which molten metal is poured into a metal cavity under the influence of earth gravity to obtain castings.

What are the design of the mechanical structure and working principle of the gravity die casting machine

1) Pedestal frame

Pedestal frame is located at the bottom of the casting machine. It was used to store water and graphite powder to cool and dip coating the models. Thus the machine can operate for a long time and model temperature is under control. Left and right water tank are separated, which make them easy to clean and can blend the water and graphite powder evenly. Considering the strong causticity of graphite, a PUC board is installed inside the water bank to prolong its useful time. The agitation effect is good and there is no dead angle.

2) Support cantilever

Support cantilever consists of a bottom beam, support rotation axis, axis seat and adjustment of casting angle. Die opening and closing, overturn, rise-fall of left and right model matching racks is completed by the supporting cantilever

3) Hydro cylinder

The hydro cylinder is installed in the middle of an electric cabinet and oil pump. It is the drive of hydraulic pressure part of the whole machine used to reclaim hydraulic oil and cool the heat produced during the motion of the hydraulic pipeline.

4) Hydraulic station and drive assembly

Hydraulic station and drive assembly are combined by hydraulic systems, including motor, oil pump, electromagnetic reversing valve, electromagnetic flow valve, manual pressure regulating valve, pipeline throttle valve and oil cylinder. It is in charge of oil supply, pressure adjustment, oil reclaim and actions of each oil cylinder.

Rise and fall→die opening→die matching→overturn→die dipping in revolution→push out the clean die→rotation and casting will be carried out one by one

5) Electrical control system

Electrical control system mainly adopts the original binding electrical components of Japan Mitsubishi Ohm Dragon, including PLC, touch screen, transformer, current transformer, voltmeter, ammeter, revolving switch, emergency stop switch, AC contactor, heat relay, air switch(380V/220V), photoelectric sensor, control box(manual/automatic), rotation, die opening and closing, model cleaning, overturn, rise and fall, overturn emergency stop. All actions will be carried out with the operation control system in the gravity die casting machine.

6)Left and right agitation electric motor assembly

Left and right agitation electric motor assembly is located at both sides of the hydro cylinder. It consists of electric motor agitation long axis, stainless steel waterleaf, bearing holder support, electric motor seat, dustproof flange and airproof nut. It blends the water and graphite powder evenly to prevent deposition. It can also blend precipitated graphite powder with water by agitation.

7)Left and right die matching support rack

Left and right die matching support rack consists of bracket copper sheathing, lead rail, soldering cup, oil tank for die opening and closing, left and right boxes, left and right oil tanks for die cleaning, left and right die connection rack. This part carries out raising, matching, cleaning of the die and revolving casting, etc.

8)Left and right revolving boxes and die cleaning mechanism

Left and right revolving boxes and die cleaning mechanism mainly consist of bearing, gear, gear shaft, hydro cylinder, positive stop, up and down shaft block, sealing element, induction block, flange, etc. It is mainly in charge of die cleaning; die dipping in rotation, front casting, and die replacement.

Delin gravity casting machinery, the models DL-550-B gravity filler is designed as manual and automatic mode, manual: controlled by a single switch, automatic: die clamping with pedal and hands (hands-clamping is designed specifically for worker’s safe operation.).

Delin Machinery is a well-known Chinese foundry machinery manufacturer, which can provide quotation and export of casting machines to various countries. You can click here: gravity die casting machine to view more details of our casting machine products.

If you want to know more details like are we manufacturers? machine function? support video and more pictures? price list? how to buy? Welcome to Send Inquiry or Chat Now or send us Email about any question on the machine, please contact us >>> Tel / WhatsApp / WeChat: +86 13960339790, Email: salse16@chinamakeco.com