How to maintain the metal casting mold?

Generally, after the metal casting mold is accepted, in order to maintain the stability of the metal casting mold in the performance state and extend the service life, it also ensures the normal progress of the mold on the casting machine and the quality of the product and reduces the production cost as much as possible. Next, Delin Machinery, which focuses on metal casting equipment, will share with you the maintenance and maintenance of casting molds.

How to maintain the metal casting mold?

First, preparation and inspection before casting

1. You must wear protective equipment, such as work clothes and safety shoes, before going to operate the casting machine.

2. Confirm the casting name and metal mold casting mold number of the maintenance metal mold casting mold.

3. Find out the sample of the casting mold of the metal casting mold, and compare it with the metal mold casting mold in use, and check the situation of the fault location of the aluminum mold casting mold.

4. According to the drawings and data in the metal casting mold file, carry out the next step to confirm the required maintenance items, and formulate a detailed maintenance plan.

5. Prepare the tools and accessories to be used and do every step carefully and responsibly according to the maintenance plan.

Second, maintenance, grinding, assembly and cleaning of metal casting molds

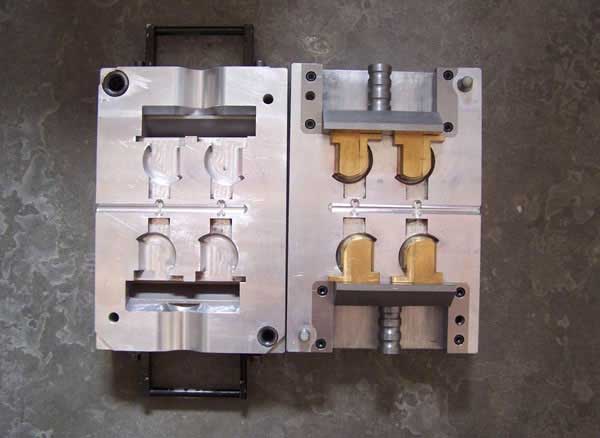

1. After the metal casting mold is used for a period of time, a large number of aluminum scraps and dirt accumulated on each moving part should be removed, especially the parting surface, cavity, core, exhaust block, overflow groove these parts. During maintenance, the metal mold casting mold should be hung on the cleaning table. Use copper brushes, shovel, rags, brushes and other cleaning tools to remove the residual products (such as aluminum skin and aluminum shavings), oil stains, and mold release agent residues on the mold. Remove any other foreign matter and other dirt. When cleaning, be careful not to damage the product parts such as cavity and core.

2. When disassembling the metal casting mold, it should be noted that the combination of each component must have a relative number. The combination of the same number can not be installed incorrectly. The wrong installation will produce flying aluminum during production, resulting in production shutdown failure.

3. Repair the metal casting mold according to the casting. Take out the residue in the cavity, and save the light in the cavity, the aluminum sticking place on the core, and the deformation place. Repair the meat, welding or changing the place so that it can be formed and demolded correctly to prevent backlash. Then check the sliders, the guide rails and the locations of the movable parts, and carry out effective mold repair and rectification.

4. Repair the metal casting mold parts (such as a cavity, ejector pin, casting pin, bolt, inclined guide column, slider and guide rail) that need to be replaced. If necessary, hand over to the quality department for inspection. After the inspection is correct, replace the damaged parts. Assemble according to the installation identification code. Beware of the wrong position and direction.

5. The cavity or core damage of the metal casting mold can be modified as much as possible. If the damage requires replacement, digging or welding repair, it should be as careful as possible, and mold repair, replacement, digging repair and welding repair should be carried out under the allowed conditions.

6. When assembling the disassembled metal casting mold parts, they must be cleaned and wiped clean before assembly. Then, on the parting surface of the metal mold casting mold (mold frame, cavity, insert block, slider core, slider seat, diverter cone, barrel, casting pin, bead, friction block and exhaust block, etc.) apply anti-rust oil, as well as guide column guide sleeve series and moving parts such as ejector rod and reset rod to apply anti-rust lubricant.

Third, maintenance operation after the production operation of the metal casting mold

1. Metal molds should be cleaned and maintained regularly after working in the casting machine. In production and use, due to the high-temperature production, the internal stress of the metal mold casting mold material will be uneven, and the stress relief and tempering treatment should be performed to eliminate the internal stress generated in the production process. To prevent the deformation and fracture of the material under the high-temperature conditions of long-term production of metal mold casting molds, affecting the accuracy of metal mold casting molds.

2. Metal casting mold (cavity) is tempered for stress relief treatment. Maintenance is generally based on the size of the casting and the batch size of the production mold. When the metal casting mold is used in the production of 8,000 molds to 10,000 molds, a stress relief tempering maintenance shall be carried out. In the later period, maintenance, stress relief and tempering treatment shall be carried out every 15,000 molds to 20,000 molds. This guarantees the service life of the metal mold.

3. When cracking or cracking occurs in the metal casting mold, first confirm whether there is any problem with the size. When there is no problem, first clean and remove the residue products or any other foreign objects on the surface of the metal mold casting mold, and then polish with 150 to 400 particles of emery cloth and oilstone thickness, and then carry out effective nitriding, ABP surface treatment or stress relief treatment to improve product forming and surface quality. When there is a problem, the processing plan should be considered first, and the maintenance treatment should be carried out after the processing is qualified.

4. Due to the wide variety of aluminum castings, the complex design of metal molds and the different conditions in production, three stress relief treatments, nitriding, and ABP surface treatment are set as the basis for maintenance.

Fourth, treatment of metal casting molds that have not been used for a long time

The metal casting mold maintenance staff shall clean and maintain the metal casting molds that have not been used for more than two months. Open the metal mold casting mold and check the internal anti-rust effect. If there is any abnormal situation, the anti-rust treatment must be performed again. Metal casting molds that have not been used for a long time must be greased to prevent rust and affect post-production. It must be cleaned and inspected before boarding.

The above is the maintenance method of metal casting molds shared by Delin Machinery —a well-known Chinese foundry machinery manufacturer, hope to help with you!

Delin Machinery—Delin Intelligent Technology Co., Ltd. specializes in the production of the foundry casting machine. It is a machinery manufacturing enterprise integrating scientific research, design, manufacturing, installation, debugging and consulting services. Welcome to contact us about any question on the casting machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: [email protected]