Automatic moulding machine sand shooting dissatisfaction factors

What factors can cause dissatisfaction with the sand shooting of the automatic moulding machine?

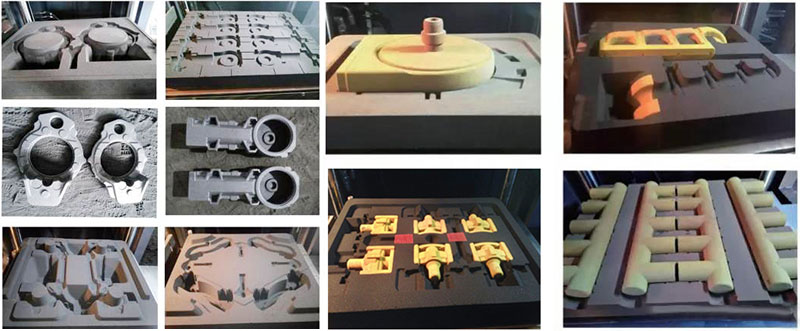

We know that if the sand injection port of the automatic moulding machine is not satisfied, it will affect the structure of the sand core, and the loose sand core structure and the quality of the sand core will directly affect the quality of the casting, so if the sand injection port of the automatic moulding machine is not satisfied.

What are the main reasons for the dissatisfaction with the sand-shooting automatic moulding machine?

First, the sand injection pressure is not enough, or there is air leakage between the automatic moulding machine body and the mold during the sand shooting process. When encountering sand-shooting dissatisfaction, the first thing to consider is whether the gas supply pressure equipment is malfunctioning. Under normal circumstances, this gas supply pressure is the most prone to problems. Many manufacturers do not pay attention to this during use, so when When the sand shooting pressure is too low, during the set sand shooting time, the pressure is too low, which will result in insufficient sand shooting, that is, the sandbox is not filled with enough sand material.

If the sand shooting pressure is found to be lower than the normal value, if the on-site staff have no operating experience, they should promptly seek help from a technician. In fact, in many cases, as long as a certain sand shooting pressure is reached, the sand shooting problem can be solved quickly.

The principle of air leakage is similar to that of sand shooting pressure. When sand shooting is not satisfied, check whether there is any air leakage in the sand feeding equipment in the molding machine production line. If air leakage is found, the reason for the dissatisfaction of sand shooting is due to this leakage. If there is no air leak, please look at the second factor.

Second, the mold structure design is unreasonable, the process is too complicated, the air conduction, and the exhaust is not smooth. If the first point cannot be solved, it is necessary to consider whether the design of the sandblasting hole of the molding machine is unreasonable and whether the mold is too complicated. These are all technical issues. You can find professional technicians for repairs.

According to the size and specifications of the mold, reasonably arranging the holes of the sand shooting mold is also an effective method to solve the sand shooting dissatisfaction of the automatic molding machine. Taking into account the complexity of the hot core box mold, this can also cause many problems, such as local sand mold defects.

Third, if the temperature is too high, the molding sand will condense before it can fill the cavity.

The solution is to adjust the mold to fit tightly to avoid air leakage during the blowing process. The place where the molding sand cannot always be blown may be suffocated, and vent holes should be opened. Lower the temperature to allow time for the loose sand to fill the cavity and then condense.

This is a little experience of Delin Foundry Machinery Company, which may help solve your problem.

Delin Machinery is a well-known Chinese foundry molding machinery manufacturer, which can provide quotation and export sand casting equipment to various countries. It is a machinery manufacturing enterprise integrating scientific research, design, manufacturing, installation, debugging, and consulting services.

Our company is a professional manufacturer with years of experience in the production of automatic sand casting equipment. We have a professional design and production team to produce a high-quality foundry molding machine.

You can click here: automatic sand casting equipment to view more machine introduction, and maybe you are interested in machine working video: DL-3040 automatic sand casting equipment working process video

If you want to know more details like are we manufacturers? machine function? support video and more pictures? price list? how to buy? Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: [email protected]