How to maintain the automatic molding line?

User maintenance and repair are the continuous guarantees of the high reliability of the automatic molding line

After the automatic molding line is put into operation, can users maintain reliable operation? From the perspective of domestic users, the reliability of the sand molding equipment provided by the same supplier for different users is very different. The management level, the quality of operation and maintenance personnel, daily operation, maintenance and repair have a lot to do.

1. Strict scientific management system

There must be a strict scientific management system in the use, maintenance and repair of the molding line.

Establish correct operation, maintenance and repair procedures, and have clear responsibilities, rights, and interests to the operators, and the work organization of operation, maintenance and repair cannot be separated.

Its personnel must be responsible for both operation and maintenance and repair, to ensure correct operation, regular maintenance and immediate repair;

If the work organization of operation, maintenance and repair are separated, the operator is not responsible for maintenance and repair, and the maintenance and repairer are not responsible for the operation, which is very detrimental to the reliability of the molding line.

2. Cultivate a high-quality operation and maintenance team

Generally speaking, the higher the degree of automation, the higher the quality requirements for operation and maintenance personnel. Therefore, in the use, maintenance and repair of the molding line, a team of high-quality operation and maintenance personnel must be cultivated;

Operators and maintenance personnel must have a strong sense of responsibility, not only must have excellent skills but also have certain mechanical, hydraulic, pneumatic and electrical knowledge.

It is must also have the ability to analyze and solve problems, be able to troubleshoot in the shortest time, reduce downtime, and improve the reliability of the molding line.

3. Correct operation

In the process of using the automatic molding line, the operation and maintenance personnel must perform correct operations according to the automatic molding line operating rules. If the operation is improper, it will damage the equipment and affect its reliability. And may bring unnecessary economic losses, sometimes there will be a long period of downtime;

Especially when adjusting the original position or repairing and maintaining, misoperation is more likely to occur, so you must be especially careful, and the operation and maintenance personnel should cooperate with each other and operate only when they are confirmed to be correct.

4. Regular maintenance

During the use of the automatic molding line, the operation and maintenance personnel must perform maintenance in accordance with the relevant regulations of the automatic molding line maintenance; regularly add oil to the lubrication points;

The wearing parts (such as dust scraping ring, guide sleeve, sealing ring, gasket, cleaning brush and sand scraping board, etc.) should be checked frequently. If any abnormality is found, it should be replaced immediately.

Due to the relatively poor environment of the automatic molding line, especially the dust, some moving parts (such as the horizontal guide rod and the vertical guide sleeve dust ring) must be kept clean.

To reduce wear and increase its service life. Check the hydraulic oil frequently to see if it is deteriorated or contaminated;

If necessary, sample the hydraulic oil for testing. If any abnormality is found, it must be replaced immediately. The hydraulic filter should also be checked frequently to see if there is any abnormality. If it is found that it can no longer be used, it must be replaced immediately;

For pneumatic systems, not only regularly refuel the lubricator, but also frequently check whether the filter element of the water filter is blocked. Only regular maintenance can extend the life of the equipment and ensure the high reliability of the molding line.

5. Serious maintenance

During the use of the automatic molding line, the operation and maintenance personnel must carefully repair the faults that occur in the molding line. Even minor problems must be repaired immediately to prevent minor problems from turning into major failures and causing downtime.

The molding line should also be repaired regularly and overhauled regularly to avoid using it with illness. The user must also have a spare parts library so that it can be provided immediately in case of maintenance.

For the failure of the hydraulic system, special attention must be paid to the contamination of hydraulic oil during maintenance. If there is any leakage or valve stuck, etc.,

Wipe the leaking part of the valve and its surroundings with silk cloth or lint-free cloth before disassembling and repairing to ensure that dirt does not enter the hydraulic oil, and the reliability of the molding line must not be affected by maintenance.

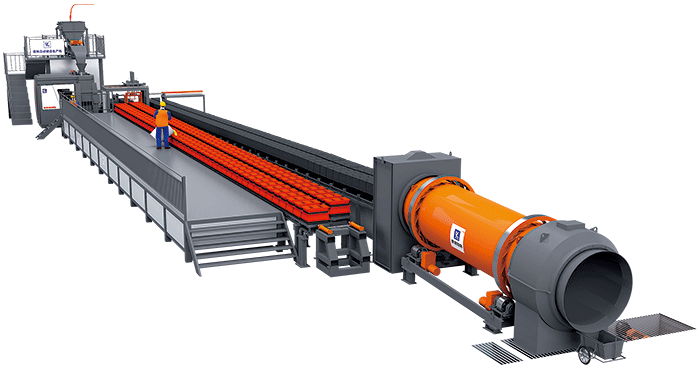

Delin Machinery specializes in the production of the automatic molding line. It is a machinery manufacturing enterprise integrating scientific research, design, manufacturing, installation, debugging and consulting services. You can click here: automatic green sand molding machine to view more introduction, and maybe you are interested in machine video: DL-3040 automatic green sand molding machine working video

Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: salse16@chinamakeco.com