What is the application of low pressure die casting machine?

The application of low pressure die casting machines are widely used in the production of castings in the production of small cars, motorcycles, instrument panels, textile equipment and aerospace industries. It is a general equipment for low pressure casting of profiles. Especially the application of aluminum alloy low-pressure casting machine has become more and more widely used in recent years.

The low-pressure casting machine may not be very clear to everyone, but when it comes to people’s transportation tools, we all know which ones. The components of this transportation tool that people use are all produced and processed by low-pressure casting machines.

The low pressure casting machine is composed of a server, a hydraulic drive system, a molten pool holding furnace, a liquid level charging equipment, an electrical system and a grinding tool refrigeration system.

Why is the application of low pressure die casting machine more and more extensive

Nowadays, there are many aluminum alloy profile crafts used in daily life. Due to the low density of aluminum alloy, but the relatively high compressive strength, it has long been close to or can be said to have exceeded high-quality steel, and has good ductility.

And it can be produced and processed into a variety of aluminum profiles, with high-quality conductivity, heat transfer and corrosion resistance. It is widely used in industrial production and the demand is only second to steel. The low-pressure casting machine is most suitable for producing aluminum casting products.

In addition, aluminum alloy profiles are the most common type of rare metal structural raw materials used in industrial production and have been used in airlines, aerospace, small cars, machinery and equipment manufacturing, ships and chemicals.

With the rapid development of economic and social development, the requirements for aluminum alloy welded parts are increasing day by day, which makes the research on the weldability of aluminum alloy profiles in-depth. At this stage, aluminum alloy profiles are the most used aluminum alloy. Therefore, the application of low pressure casting machines will become more and more common in the future.

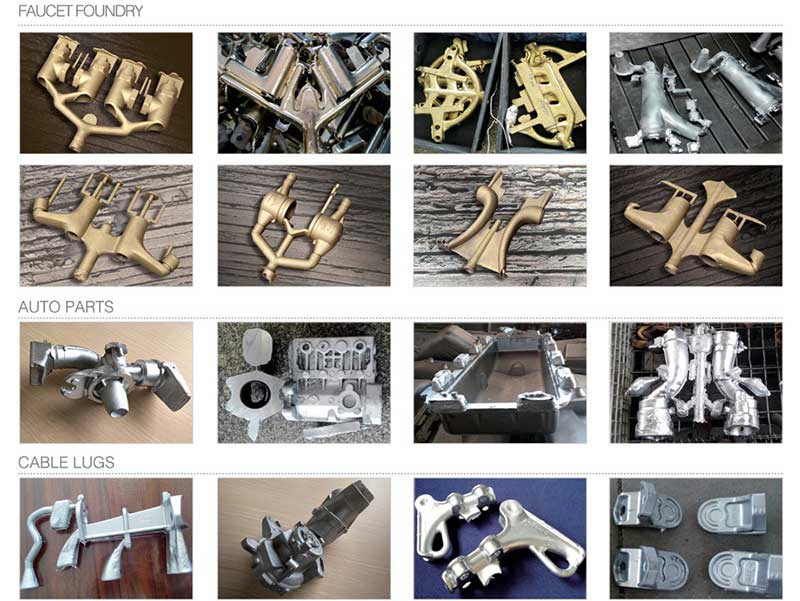

What are the general applications of low pressure die casting machines

Casting material: non-ferrous alloy

Casting quality: dozens of grams to dozens of kilograms

The surface quality of castings: good

Casting structure: complex (sand core available)

Production cost: high production cost of metal type

Scope of application of low pressure die casting machine: small batches, preferably large batches of large and medium non-ferrous alloy castings, thin-walled castings can be produced.

Process characteristics: The castings have a dense structure, high process yield, simple equipment, and various casting molds can be used, but the productivity is relatively low.

Brief description: low pressure casting, a casting method in which liquid metal is filled into a mold and solidified into a casting under the action of low pressure gas. The low pressure casting was initially mainly used for the production of aluminum alloy castings and later expanded its use to produce copper castings, iron castings and steel castings with high melting points.

Many people are not very familiar with the actual application of low pressure die casting machines. In fact, this kind of equipment is very common in modern processing and production industries and has become one of the indispensable equipment in processing and production.

In the process of automobile manufacturing and instrument production, the use of low-pressure casting equipment can meet the processing and production standards, and the equipment is also widely used in textile production sites.

The composition of the low pressure casting equipment manufactured now is very simple, mainly composed of hydraulic systems and electronic control devices. The operation method of the equipment is also very simple and convenient, so it has been widely developed after its launch.

In the automobile manufacturing industry, various accessory products need to be made on a regular basis. The application of low pressure die casting machines plays an important role in the process of processing and production. This kind of equipment is also widely used in the aerospace field and the textile industry.

The development has a positive effect. The design and production of low-pressure casting equipment have also undergone many improvements. The equipment introduced now has more advantages in structure. The structure is very simple, mainly composed of hydraulic systems and pressurizing devices, which can provide more convenience for production.

Users need to pay attention to several issues during the application of low pressure die casting machines. First, they must have a certain understanding of the working principle of the equipment, and secondly, be familiar with the operation methods. Different types of low-pressure casting equipment also play a certain role in the development of related industries, so the selection of equipment is also very important.

Delin Machinery specializes in the production of the low pressure die casting machine. It is a machinery manufacturing enterprise integrating scientific research, design, manufacturing, installation, debugging and consulting services. if you want to know more about the application of low pressure die casting machine, contact us as you free!

You can click here: low pressure die casting machine to view more introduction, and maybe you are interested in machine video: low pressure die casting machine working process video

Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: salse16@chinamakeco.com