What is structure of core shooting machine?

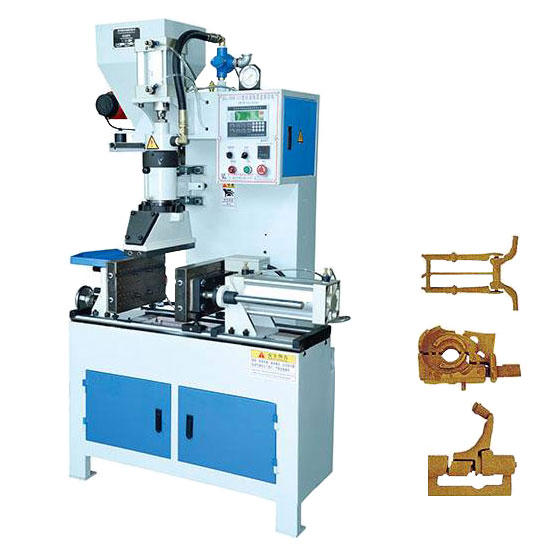

This article takes the heat core box sand core shooting machine as an example to analyze the main structure and working principle of the core shooting machine.

The core shooting machine mainly consists of the following parts

- Sand hopper

- Sand shooting mechanism

- Base-frame

- Pipeline

- Electrical devices

- Sand hopper

The sand hopper is positioned at the left side of the column which is used for sand core storage and conveying. It is a circular cone or tetragonal pyramid groove. The sand core will fall into the sand-shooting drum via the outlet of sand hopper.

- Sand shooting mechanism

The sand shooting mechanism consists of a shooting head, sand-shooting drum, whirling stand, and cylinder as well as sand shooting valve controlled by the operating valve. When shooting, the sand shooting valve will open while the compressed air in the air storage chamber will enter the sand-shooting drum. The core sand in the drum will be shot into the core box by the shooting head. After shooting the sand, the inlet of shooting valve close while its outlet will open and the residual gases inside the shooting cavity will be discharged by the outlet valve and muffler.

- Base-frame

The base-frame consists of an upright column, base, clamping cylinder and core-pushing cylinder. The upright column is connected with the rear part of the base-frame and its upper part is connected with the sand hopper. The hollow part of the upright column is also used as an air storage chamber. The clamping cylinder, core-pushing cylinder and core pulling cylinder are situated in the front of the base. The back cylinder of the base contains an outlet valve which is used to discharge the water in the air storage chamber.

- Pipeline

This core shooting machine is operated by a six-position manual operating valve, a two-position four-way air operated directional valve. Following two programs can be realized by turning its hand knob manually:

①Core box clamps-sand-shooting head clamps-sand shooting-shooting head rises-heating-core box open-die holder-take out the sand core

②Core box clamps-core pushing-shooting head clamps-sand shooting-shooting head rises-heating-core pulling-core box opens-die holder

③Before starting or after machine operation, the hand knot should be turned to the zero position

After opening the compressed air pipe strobe, all parts of the machine should be under the following status:

A、The compressed air used for sand shooting enters into the air storage chamber via a pressure regulating valve. The shooting pressure can be adjusted by the pressure regulating valve.

B、The controlling compressed air enters the operating valve through the strainer and pipe of the oil atomizer, as well as enters the clamping cylinder, shooting-head clamping cylinder and core-pushing cylinder through the pipe.

C、①When turning the hand knot of the operating valve from zero to one position, compressed air makes the plunger of clamping cylinder forward and also clamps the core box on the worktable.

②When turning the hand knot of the operating valve from I to II, compressed air makes the shooting-head clamped plunger forward and also clamps the shooting head on the core box.

③When turning the hand knot of the operating valve from II to III, air supply from the operating valve enters the sand-shooting valve through the pipe and shooting stars when the valve is open.

④When the hand knot of the operating valve is relocated at the II position, the compressed air makes the sand-shooting valve close through the pipe and the residual air will be discharged by the sand-shooting valve.

⑤When repositioning the hand knot of the operating valve from II to I, the shooting-head clamping cylinder will be recovered.

⑥When turning the hand knot of the operating valve back to the zero position, the clamping cylinder will open.

⑦When turning the hand knot of the operating valve from 0 to I position, compressed air makes the plunger of the clamping cylinder forward and also clamps the core box on the worktable.

⑧When turning the hand knot of the operating valve from I to II, the plunger of the core-pulling cylinder will be pushed to clamp the mandrel.

⑨When turning the hand knot of the operating valve from II to III, compressed air clamps the shooting head on the core box.

⑩When turning the hand knot of the operating valve from III to IV, air from the operating valve enters the sand-shooting valve through the pipe and shooting stars when the valve is open.

⑪When the hand knot of the operating valve is re-positioned at III, compressed air makes the sand-shooting valve close and the residual air will be discharged by the sand-shooting valve.

⑫When repositioning the hand knot of the operating valve from III to II, the shooting head clamping cylinder will be recovered.

⑬When repositioning the hand knot of the operating valve from II to I, the core-pulling cylinder pumps back. When the hand knot is turned from I to 0, the clamping cylinder will open.

- Electrical parts

①Temperature of the heating plate can be controlled automatically.

②Using the thermoelectric couple, temperature indicating controller and contactor inserted in the heating plate, the temperature of the heating core box will be kept within a certain range.

③Automatic signal device for solidifying time: when the shooting-head clamping cylinder returns to the original position (rise), the time relay and contactor with inductive switches start counting simultaneously. When reaching the set solidifying time, the indicator light will shine and die can be opened.

④The machine must be earth connected.

Delin Intelligent Technology Co., Ltd. specializes in the production of the core shooting machine. It is a machinery manufacturing enterprise integrating scientific research, design, manufacturing, installation, debugging and consulting services. If you want to know more details like are we manufacturers? machine function? support video and more pictures? price list? how to buy? Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: salse16@chinamakeco.com