How to safe installation and use core shooting machine?

Abstract: During the installation and use of the core shooting machine, the connection of each component should be checked to determine the stability of the connection between the components, as well as the stability of each bolt and nut.

Once installed, the quality of the product produced is also impossible to determine. Therefore, a correct installation method is very necessary.

During the installation and use of the core shooter, the connection of each component should be checked to determine the stability of the connection between the components, as well as the stability of each bolt and nut.

If any looseness is found, maintenance and repair should be carried out in time. The core shooting machine can maintain a stable working rate after it is started.

The exhaust noise of the sand core shooting machine is similar to the exhaust noise of the air hanger in the production mechanism. However, because the core shooter has a large exhaust volume and a short time during core shooting, the noise produced is annoying.

All of us in the foundry know that no matter it is a sand core shooting machine or a shell core machine, there will be a lot of noise, and it will affect our hearing for a long time. So how to solve this problem? Answer: Install an exhaust muffler for the core shooter, so as to harm the noise.

Before the core shooter is used, it is also necessary to have a full understanding of the equipment, and clarifying the installation and use precautions of the equipment will help improve the working speed of the equipment. Usually, before using the core shooting equipment, it is necessary to check all the cylinders and gas paths of the equipment, so as to avoid air leakage and other phenomena in the device, and it can also be directly eliminated when quality problems are found.

In addition, during the cleaning process, it is also necessary to keep the contact of all moving parts of the equipment clean, whether it is a guide sleeve or other devices, it needs to be kept clean.

The key points of using the core shooting machine:

1. Before starting the core shooting machine, turn on the ventilation device, and at the same time let the water in the air storage bag, then turn on the air source, test the car with no load, and make sure that the operation is normal before using it.

2. During operation, it is strictly forbidden to touch the core box by hand to prevent fingers from being pinched.

3. When shooting sand, the operator should avoid the sub-box surface and sub-box, so as to prevent the bad sealing of the sub-box surface from sandblasting and hurting people.

4. Make sure that the sand shooting cylinder has enough core sand (generally not less than 2/3 of the volume of the sand shooting cylinder) before sand shooting. It is strictly forbidden to shoot without sand.

5. Wear protective equipment such as protective glasses.

6. Check the core shooter and ventilation device to make sure they are in good condition.

7. Before closing the power supply for heating, turn on the water source of the water-cooled sand-blasting board, and check the heating device and related electrical facilities to make sure it is stable.

8. Check the tooling facilities such as core box, sand-shooting plate, sand-shooting head, sand-shooting cylinder, gate plate, etc., to make sure that they are clean and intact, and the mutual assembly should be stable and stable.

9. When taking the sand core from the core box and piercing the sand hole on the opposite sand plate, wear gloves to prevent hands. Sand cores taken out from the core box should be stacked neatly to prevent collapse.

10. After the work is completed, it is necessary to clean up the sand shooting cylinder, the residual sand in the sand shooting head, and the sand bucket in time, clean the sand accumulation in the core box and the core shooting machine, clean up the worksite, and make sure that the worksite is clean.

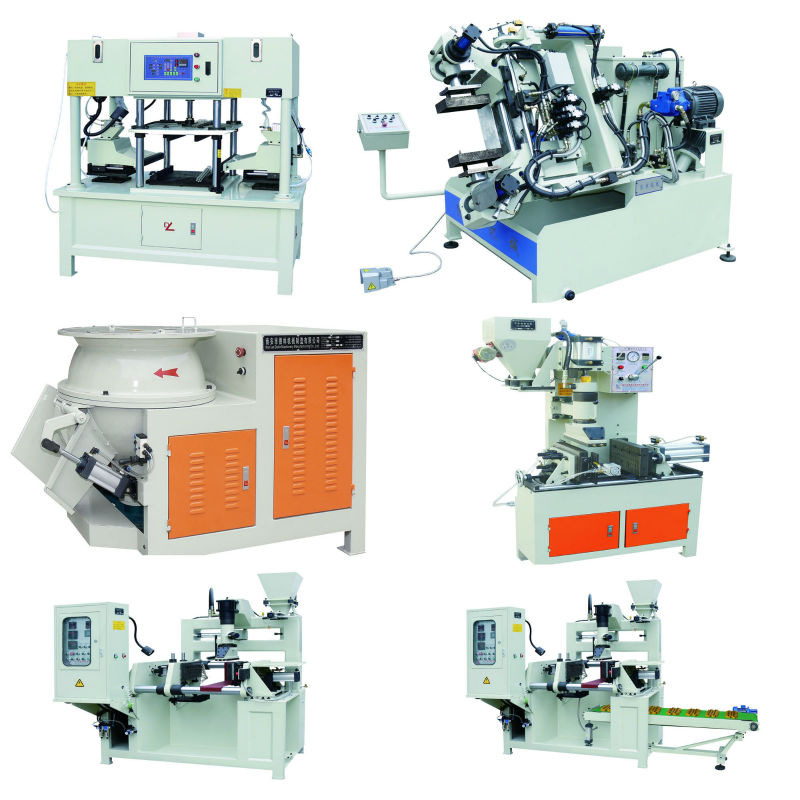

You can click here: automatic sand core shooting machine to view more machine introductions, and maybe you are interested in the machine working video: core shooting machine working process video.

By the way, If the machine is purchased from our company, we have technicians to come to install and train. If you want to know more information like are we manufacturers, machine function, support video, and more pictures, price list, how to buy, Welcome to Call / WhatsApp or send us Email about any question on the machine, please contact us >>>Tel / WhatsApp / WeChat: +86 13960339790, Email: salse16@chinamakeco.com