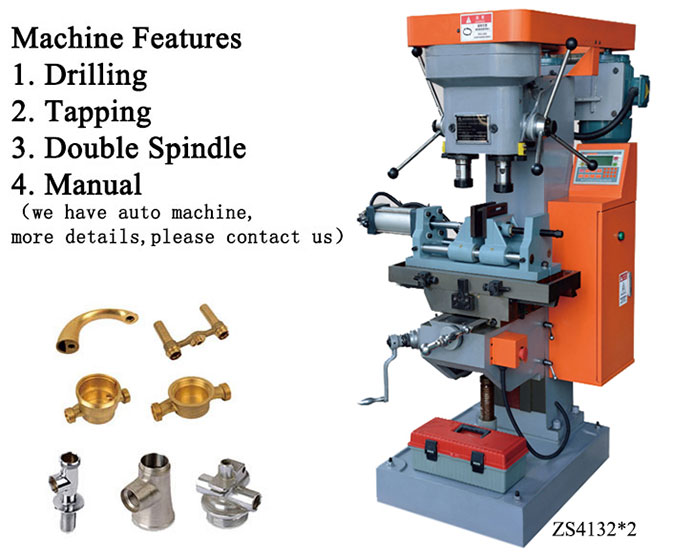

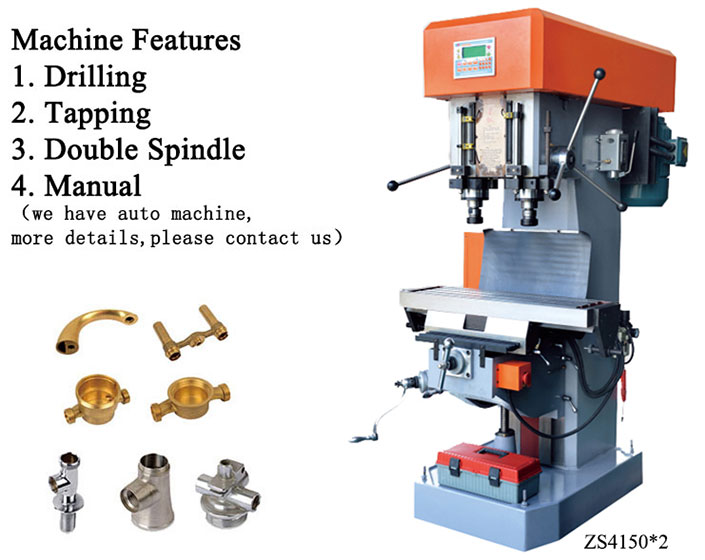

Manual Double Spindle Drill and Tapping Machine

This double spindle drill and tapping machine, manual rocker operation, also called pneumatic double spindle compound machine tool. It is suitable for batch parts processing, drilling and tapping can be completed at once. model ZS4132*2, ZS4150*2

Product Description

1. The double spindle drill and tapping machine are suitable for processing large quantities of parts. Drilling and tapping are completed at one time, with high efficiency.

2. The fuselage has a compact structure and good rigidity.

3. The spindle is made of high-quality alloy steel, hardened and heat-treated, precision ground, and high wear resistance.

4. The sliding surface is quenched by super audio frequency and has a lubricating device to ensure the service life of the sliding surface.

5. Pneumatic device and buffer device are used to move the worktable from left to right, with small vibration and fast movement.

6. The handle of the knife adopts a drawbar type, which is not easy to fall off and has high safety.

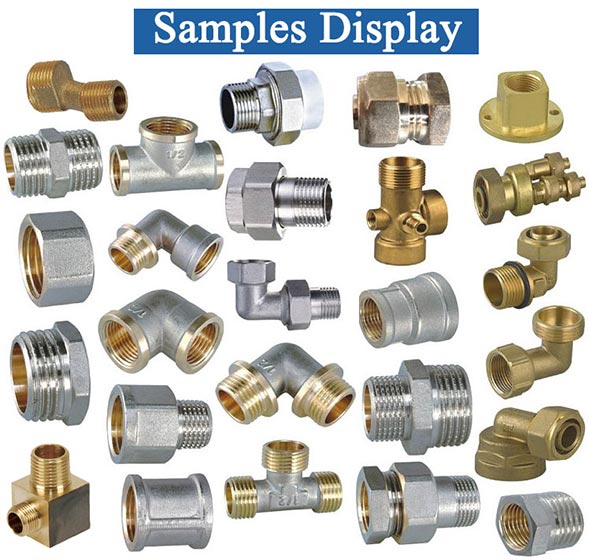

Application

This double spindle compound machine is applied to drill and tap the brass faucet, valves, sanitary ware products, door control hardware, fire hydrants, auto parts and other processing, reduce manual operation, one person can watch multiple devices, fast efficiency and high precision.

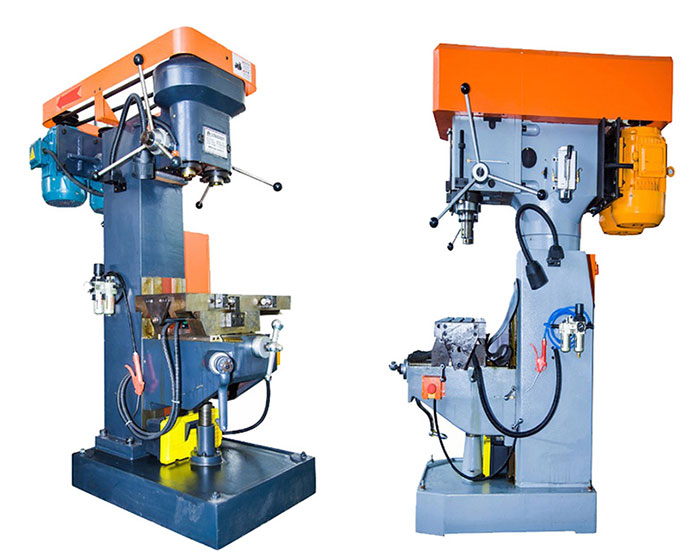

Double Spindle Drill and Tapping Machine Display

Workshop Production

Packaging & Shipping

1. Plastic film packaging and put in plywood wooden cases or according to customer’s requirements.

2. Shipping: Container transport.

Technical Parameter

| Type | ZS4132*2 | ZS4150*2 |

| Performance Dimension | 1200*610*1450(mm) | 1390*1110*1750(mm) |

| Machine Weight | 600KG | 1200KG |

| Worktable Size | 600*230mm | 800*230mm |

| Worktable Stoke Length | 150mm | 240mm |

| Main Spindles number | 2 unit | 2 unit |

| Spindle Forms | NT30 | MT4 |

| Spindle Power | 3KW/4P | 3KW/6P |

| Spindle Rotating Speed | left: 880/1400 (r/min); right: 880/1400 (r/min) | left: 675 (r/min); right: 1000/675 (r/min) |

| Spindle Outer Diameter | 86mm | 90mm |