Working hours:Mon - Sat 8.00 - 18.00 Call Us: (+86) 13960339790

Automatic Core Shooter Machine With Nylon Conveyor Belt

DL-361 core shooter machine is used to making sand core for castings. This is a hot core box automatic core shooter machine with a nylon conveyor belt. There are two models, DL-361-A and DL-361-A-01, the only difference between them is whether there is a protective shell, and DL-361-A-01 is yes.

Product Description

- The foundry core shooter is applicable to the valve, water tag, hardware fittings, hydraulic pressure and small workpieces of variety cores in the air-powered industry.

- This automatic core shooter machine is automatically injected sand, the conveyor belt automatically upturns to receive the finished sand core. It is used to produce furan resin series heat core box sand, urea resin series heat core box sand and pre-coated sand core-making. Especially, it can meet the core-making requirements of heat core box processing in the cast copper and cast aluminum industries which adopt three constituent resins of complicated shape and low structural strength (applicable to casting sand with poor liquidity).

Characteristics of mechanical structure and appearance are as follows:

- With the human-computer interface, imported high quality electrical and air controlled components, precise and reliable control and convenient operation are guaranteed.

- Manually operated with two functions of unicycle and multi-cycle; summating counter and pre-set counter are set.

- The shooting head rotates for 50° to receive sand. It is far away from the high-temperature area but within the range that personnel can operate, therefore, it is easy to clean the shooting hole manually.

- The core shooter machine can be plainly moved as a whole. After die is closed, the die will move along the X-axis and Y-axis to make the shooting hole alignment more convenient and precious.

- Core-pulling rack is set for the moving die which meets special requirements of the die. If the core doesn’t need to be pulled, switch off the core-puller.

- The angle of the running sand in the sand hopper reaches 70°. Moreover, a vibrating motor is installed to meet the core sand requirements of the cast copper and cast aluminum industries using sand with core breakdown properties and with poor liquidity.

- Die adjustment margin is set to make it easy to use different dies and lower the requirements of the mold exterior physical dimension.

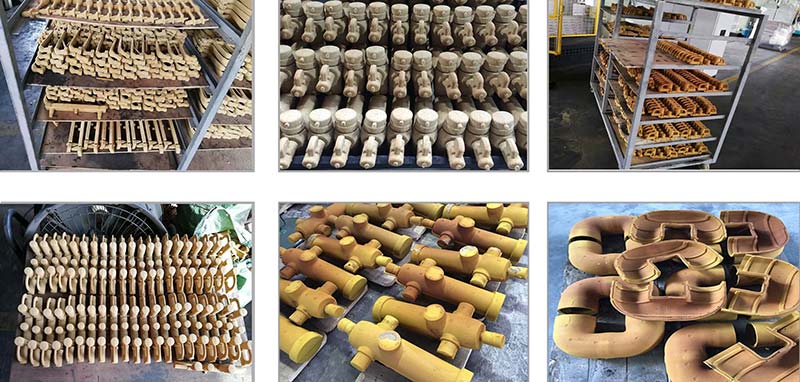

Samples

Machine Display

Technical Parameter(DL-361-A-01 same to DL-361-A)

| Performance Dimension | 3500*1480*2350mm |

| Net Weight of Machine | 1543kg |

| Heating Power | 10kw |

| Max. Weight of Sand Cores | 6kg |

| Max. Size of Core Box(L*W*H) | 400*280*200mm |

| Size of Heating Plate(L*W) | 350*200mm |

| Itinerary of Plunger Under Pressure | ≤30mm |

| Increased Angle of Nylon Conveying Band | 2°-4° |

| Transmission Speed | 72mm/s |

| Nylon Conveying Band(L*W*H) | 2200*400*100mm or according to client’s requirement |

| Power supply voltage | 380V/220V,three-phase four-line/single phase two-line |

| Sand hopper volume | 25kg |

| Motor power of the sand hopper | 0.25kw |

| Productivity | 40-100 core/Hour |

| Die-opening stroke | <300mm |

| Mode of core-pushing | both moving die and static die adopt air-powered core-pushing mode with its maximum stroke of 20mm |

CONTACT

Quick Contact

Welcome to contact us to get more information.