Working hours:Mon - Sat 8.00 - 18.00 Call Us: (+86) 13960339790

Automatic Molding Machine

This Is An Automatic Molding Machine To Replace Traditional Manual Hand Molding Method. It Has Compact Structure And High Safety Performance, Easy To Operate, Cover Small Floor Space And Make Low Noise.

Product Description

- The sand molding machine is stable, low power consumption, and long lifetime.

- High level of automation, easy control, and lower labor cost.

- Highly standardized, good parts interchangeable, fast and low-cost maintenance

- The sand could be compacted both inside and outside according to technical requirements, which makes the sand mold better.

- The mold release agent is sprayed automatically, which makes the molding smooth. Casting surface glossily, and no defect in the sand mold.

- Electric cabinet and hydraulic stations are all installed in the machine, which makes them compact and easy maintenance.

- Low failure rate and the machine can diagnose the failure on its own.

Automatic Sand Molding Machine Working Process

- The first step is to convey the sand to molding machine;

- The second step is shooting the sand to the mold, and compacting up and down;

- The third step is to put the sand core into the mold and compacting up and down until being a forming die;

- The fourth step is unloading the sandbox;

- Then molding placement;

- Finally, pouring the iron water into the sand mold. When it is cold, the mold is finished.

What Machine Suitable For Manufacture?

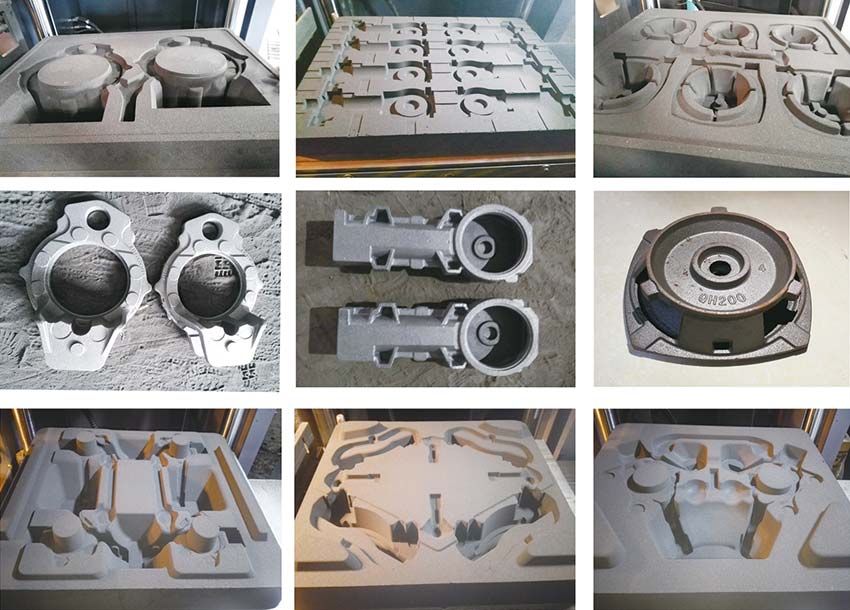

The sand molding machine is widely used in manufacture castings, machinery parts, auto and motorcycle parts, valves, bearings, cylinder head, flywheel housing, brake caliper, but also pipe fitting, shaft, covers, like T joint, elbow, clamp, etc. More competitive for those products require inner sand core. We also support customized, customer can send us sample pictures, then we will make a good recommendation for you.

Machine Display

Production Workshop

Main Specification Technical Parameter

| Contents | DL-ZX3040 | DL-ZX4050 | DL-ZX5060 | DL-ZX6070 |

| Size of sandbox | 350*450mm | 410*510mm | 500*600mm | 600*700mm |

| Thickness of sandbox | up 80-150mm

down 80-150mm |

up 80-150mm

down 80-150mm |

up 80-190mm

down 110-190mm |

up 120-200mm

down 120-200mm |

| Molding speed(s/mold) | 36 s/per mold | 36 s/per mold | 38 s/per mold | 42 s/per mold |

| Compacting pressure | ≤10MPa | ≤12MPa | ≤14MPa | ≤14MPa |

| Air consumption | 0.3m³(normal) | 0.3m³(normal) | 0.5m³(normal) | 0.6m³(normal) |

| The humidity of sand mold | 2.8%-3.5% | |||

| Drive method | Electric-pneumatic-hydraulic | |||

| Thickness of template | 20-25mm | |||

| Power supply | AC380V,50HZ, or according to your requirement | |||

| Power of the machine | 15KW | 15KW | 15KW | 24KW |

| Net weight | 5T | 7T | 9.5T | 15.5T |

| Machine size (L*W*H ) | 4150*1890*3050mm | 4080*2100*2980mm | 4400*2100*3200mm | 4710*2410*3540mm |

CONTACT

Quick Contact

Welcome to contact us to get more information.